- Home

- Servicii taiere laser Romania

Servicii taiere laser Romania

Our laser cutting services are made with modern and precise equipment for grade 10 results. Here are some advantages of laser cutting offered by our team:

1. Higher accuracy

The laser beam is very small but strong at the same time which ensures a very high cutting precision, and in this way can be used for various processes.

Thus the laser beam melts and evaporates any material with a high accuracy – and in this way we make various projects.

2. Reduced charging time

Another benefit of laser cutting is that it is an economical cutting process for various projects. That’s because the beam doesn’t use that much energy.

Servicii profesionale de debitare laser

3. Providing complex services

There is no project too complex for the laser cutting process offered by our team. The very strong laser is used to cut as fine as possible any material and causes very little deviation on the cutting area.

4. Fast cutting speeds

By laser cutting we can make various projects faster, if we use traditional cutting methods. Especially when it comes to complex projects. When comparing laser cutting with other cutting processes such as water or plasma, the laser beam is the best decision because it ensures a faster working process.

Choose our laser cutting services and make sure that any project is completed with the help of the Laser Processing Romania team.

Laser cutting comes at an attractive cost, as no expensive tools are required and the equipment costs are lower. Sheet processing is economically possible even in very small batches. Laser cutting derives its potential from the small focusing diameter of the laser beam and the resulting narrow cutting gap, high feed rates and minimal heat effect on the material.

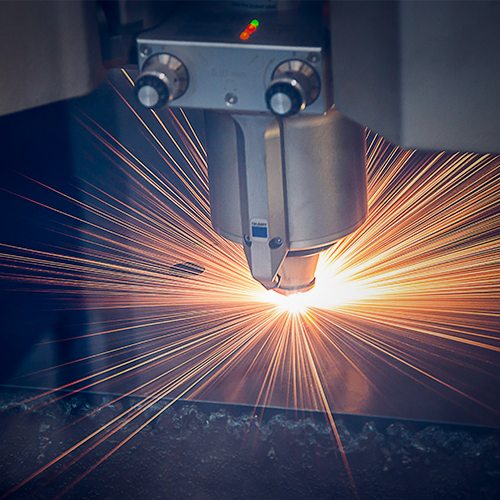

Laser cutting means cutting panels of laser material. At Laser Processing, these panels are metal sheets, stainless steel or aluminum with thicknesses of 0.5 mm to 4 mm. A focused, high-energy laser beam is aimed at these panels, strong enough to melt and evaporate the material on impact, until the metal is separated and the cut is made. The resulting metal vapors are expelled with special gases and high pressure.

A laser is an extremely flexible, computer-controlled tool that does not require pressing tools for training. Sheet processing can begin with simple vector data for the desired shape. The laser can cut virtually any solid body with laser beams and evaporation of the resulting material. The laser cuts wood, plastic and CFK or even steel, tin and aluminum. The Laser Processing team specializes in laser cutting of metals.

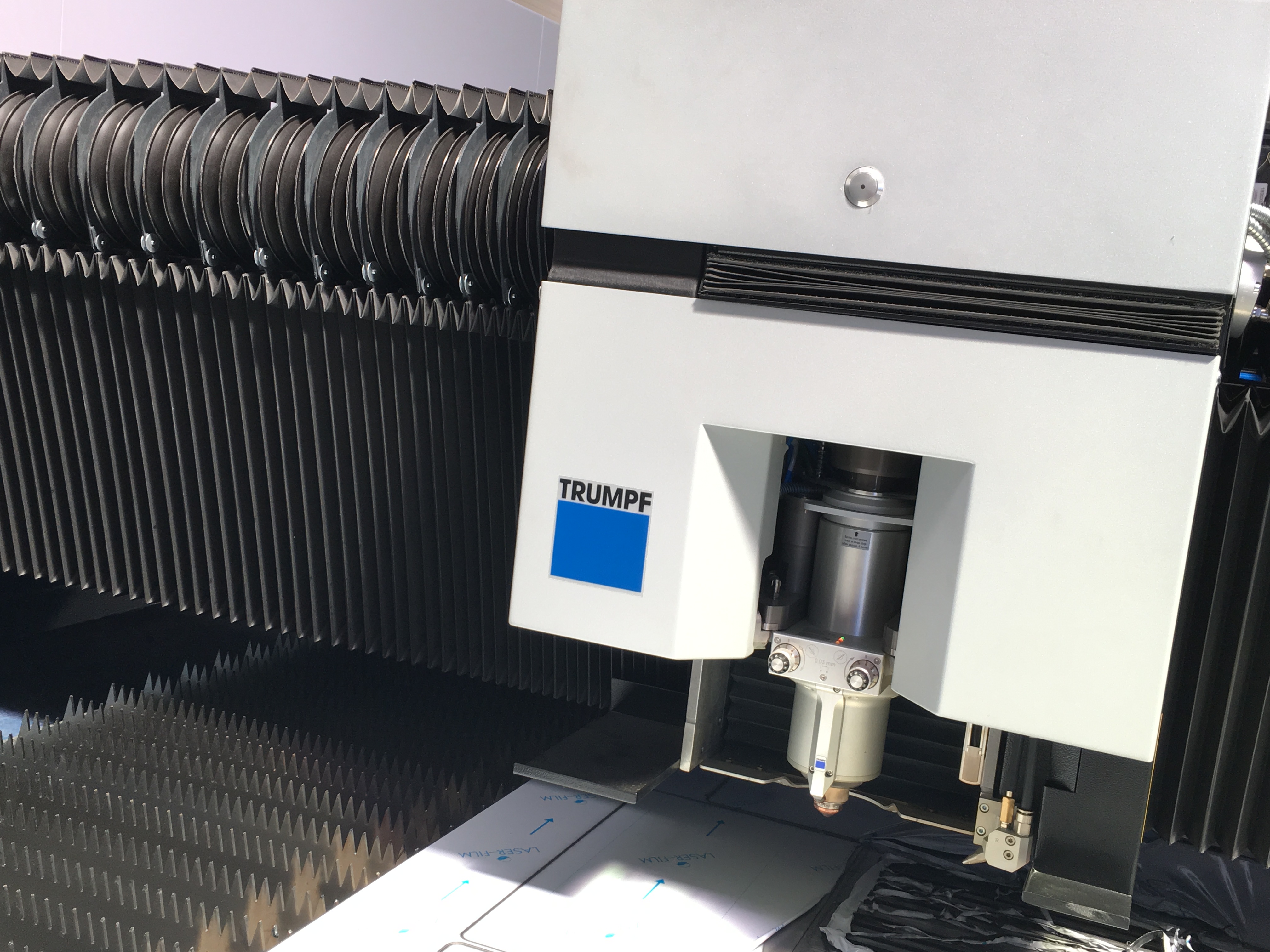

Debitare profesionala cu laser si utilaje Trumpf

Alege servicii profesionale de taiere laser in Bucuresti

Another special feature of the laser cutting board is the high material utilization. Additional processing steps, such as laser engraving, can be performed in another processing step. Because the cutting method has no contact, the laser cutting machines barely suffer any wear. Dust load and material waste are reduced compared to CNC milling or metal pressing. The material to be processed must not be fixed as tightly as, for example, to the press, which protects the metal sheets.

Laser cutting technology is ideal for producing precise cuts of stainless steel plates in different thicknesses and is distinguished by its versatility. Laser cutting is a very popular method for cutting stainless steel plates up to a thickness of 20 millimeters.

The physical properties of concentrated light beams make them ideal for use as a cutting tool. Laser light waves all have the same wavelengths and oscillate at the same frequency. Experts refer to them as monochrome light waves, which are also consistent. Together with the parallel direction of light waves, it creates a concentrated beam of light with a high power density. A properly formed laser beam is a powerful cutting tool for stainless steel due to its high power density.

Servicii Debitare Laser in Bucuresti

Laser cutting is a relatively used option for machining stainless steel. This is due, in the end, to the absence of any form of contact in the laser cutting of stainless steel. The high precision of the laser beam means that only the local areas on the stainless steel side are exposed to a thermal change of the laser cut – a minimal area of the cutting edge, which is why laser cutting is a particularly gentle method on the material. The ability to form precise contours and cuts also ensures that the rest of the piece actually remains unstressed.

Simply, the high concentration of light beams ensures laser cutting is a powerful method of processing stainless steel. When these concentrated light beams hit the stainless steel material, this point becomes extremely hot. This process takes place extremely quickly and leads to melting or vaporization of the material. When laser cutting, the light beam practically penetrates the stainless steel. The molten metal is blown to create the hole, signaling the beginning of the cutting process. The concentrated beam can move them along the desired contour and can create complicated cuts.