Laser cutting is one of the most efficient methods of cutting steel, stainless steel or aluminum sheets used in various industrial fields: construction, automotive, agri-food, oil, transport, etc.

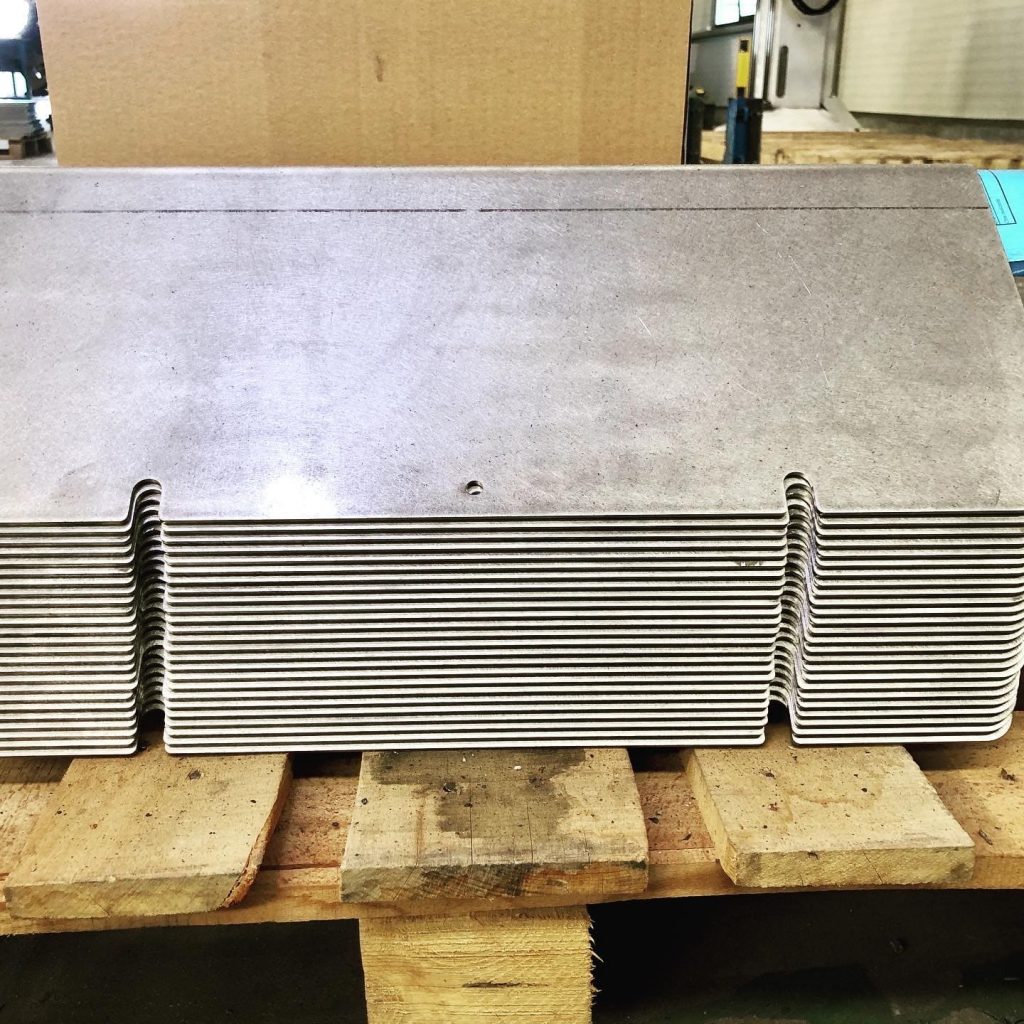

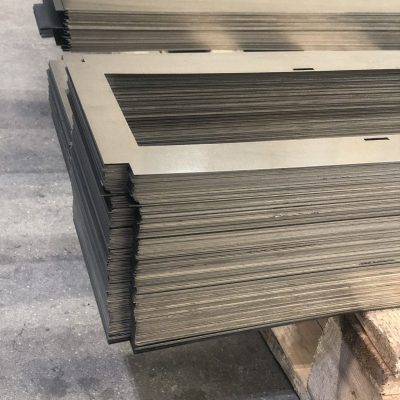

At the same time, it is a technology that considerably reduces production times and costs. The cut pieces have no burrs and are very little thermally influenced, being easily workable later if they are painted in an electrostatic field or are subjected to heat treatments and mechanical processing.

The definite advantages of metal laser cutting compared to mechanical cutting are represented by the ease of execution of the works but also by the precision that laser cutting offers. Also, the risk of deformation of any kind of laser cut material is reduced to a minimum.

Laser Cutting Services in Bucharest to European standards

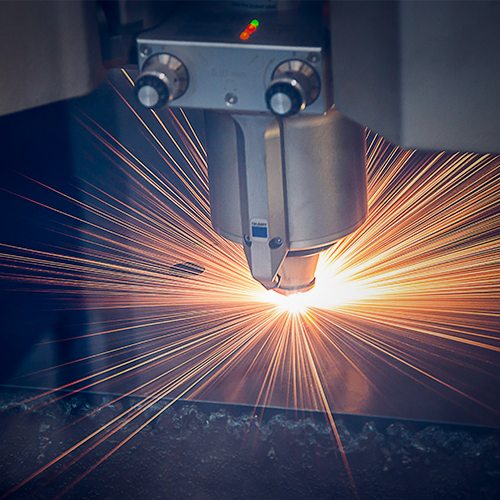

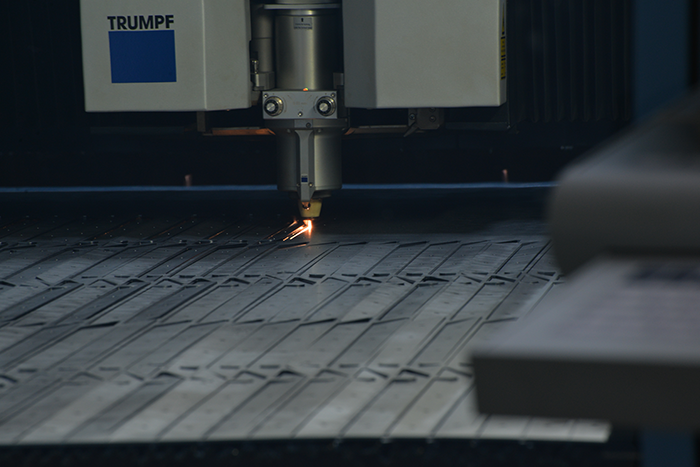

The Laser Processing team uses sheet metal laser cutting equipment that is highly efficient and accurate to create high quality parts. This cutting process will melt the excess material by burning or vaporizing, after which a strong jet of gas will remove any type of residue from the metal processing process. In the end you will get a very well finished product.

Our metal laser cutting services are executed with modern and high-performance equipment that ensures the success of any project. Thus, the Laser Processing team is here to help any business by offering professional sheet metal and metal laser cutting services.

| Contact |

Laser cutting of materials is usually used in industry, but in recent years it is also used in increasingly diverse fields such as interior design, advertising, DIY, architecture, landscaping, product design.

The laser cutting process is ideal for cutting steel that has a maximum thickness of 25mm. This process is extremely precise and will achieve a slot width that will be very small, and in this way you can cut precise contours and even small holes with precision. The quality of the edge is very good and with low roughness with very small residual lines.

Another advantage of the laser cutting process that we must take into account is the degree of reliability offered. In addition, the lifespan of consumables is very long, with a very good automation process so that all operations performed by laser cutting are performed with maximum precision.

Given that the laser will not have any physical contact with the metal on which it will be worked, there will be no form of wear on both the equipment and the material – the latter will not be contaminated at all. Compared to traditional cutting tools, laser cutting with the help of modern machines will produce very high quality finished parts with fine edges.

Laser Processing Romania-Laser cutting in Bucharest

Among the few methods to reduce the processing time and the final delivery of the finished material, we find the laser cutting services offered by the Laser Processing team – so we will reduce the working time and final costs compared to the classic methods. with laser offered by our team are very well made, eliminating the risk of ugly deformations or even damage to parts. We invite you to discover the range of professional mechanical processing services.

Are you looking for a laser cutting company in Romania to help you complete your projects?

The Laser Processing Romania team now comes to your aid with the complete range of professional sheet metal / metal laser cutting services at high standards to help you have the most successful projects and with results beyond expectations.

This process of cutting metals is very efficient because it can cut various materials regardless of their thickness. Basically, the laser is focused in a strong point and has a very high precision, and when it touches the piece, a great heat will be emitted to start the cutting process.

Having all the power focused in a single fixed point and with a diameter of half a millimeter, very fine and precise cuts will be obtained without teeth or edges.

The benefits of laser cutting services offered by Laser Processing:

1. A wide range of metals and materials can be cut

We can cut various materials needed in industrial processing from aluminum, steel, sheet metal to non-metallic elements such as plastic and glass by professional laser cutting.

Thus, this sheet metal / metal cutting process makes it highly sought after for its precision and for the freedom of cutting.

2. Freedom of movement

Because the laser beam is concentrated at one point locally, it is obvious that the rest of the part will be less thermally stressed. Due to the high flexibility, the sheet metal cutting process offered by Laser Processing Romania is very often used in various projects.

Contact .

Of all the options that exist in precision machining, one of the most recent is laser cutting. In short, the laser cutting process consists of concentrating a beam of light on the cutting surface.

The laser cutting process uses a precision mirror system, a converging focusing lens, the high power laser beam and the CNC system that we discussed in the previous post. Controls all aspects of the laser cutting process; from the frequency and speed of the beam to the values of the head and the part, depending on the exact order we need.

One of the interesting details about laser cutting is the need to use a certain type of material to dispose of the cut material. Argon or an inert gas under pressure is usually used, and the air can be efficient with non-mechanical materials.

This type of technique allows an increase in productivity, with clean cut edges, prevents overheating, corrosion resistance, discoloration is reduced, no rust is formed and the surfaces are free of slag.

It does not generate as much chips as the conventional cutting process.

It is perfect for preliminary and final cutting.

It can be used to create surface contours, silhouette adjustments or parts to be manipulated.

If the cutting is correct, there are no increases.

Laser cutting of metals can be applied to any material, whether soft or hard are used. It is commonly used in all kinds of heat-resistant alloys, such as ceramic, composite materials, leather, fabrics, sicily, plastic, etc. Depending on the material, the radiation is different.

If you are interested in precision machining work, such as laser cutting, synchronized processing is your solution. We are with you with tips and actions for each process you want to machine.

Laser cutting is a non-cutting manufacturing process for separating materials of any kind. By using laser radiation, the material is practically melted and vaporized using various technologies, so that a cutting space is created and the material is specifically separated. Laser cutting is done with all the laser wavelengths that are available, but especially with CO 2 lasers and fiber lasers.

Today, laser cutting of metals has a wide range of applications and it is difficult to imagine industrial production without it. Metals, plastics or organic materials can be cut precisely and economically with the help of the laser tool. There are also many applications where there is almost no alternative to laser cutting, such as cutting very thin sheets <0.05 mm. Laser cutting is used in all industries, from the automotive industry, medical technology, mechanical engineering to the packaging industry.

The advantages of laser / sheet metal cutting for any business

Laser cutting is contactless and has scores with short process times and high accuracy.

Apart from process gases, no auxiliaries such as cooling lubricant, etc. are required.

Almost all materials can be cut with the correct choice of laser.

Because no tools are used, the system technology is not subject to wear and is therefore inexpensive.

Reworking of cut components is usually not necessary, with the correct process parameters it is possible to cut almost without burrs, which is often a major disadvantage when perforating metal sheets, for example.

Laser cutting is extremely flexible, which means that the production of complex cutting contours on one side can also be economically implemented.

Laser cutting with nozzle

Laser cutting in combination with a cutting nozzle is the most common variant of the process. With this type of cutting, the laser beam is guided by a cutting nozzle and focused. Depending on the cutting process, various process gases are used, which are blown coaxially through the nozzle into the hole at high pressure.

Laser fusion cutting is used on metals and is characterized by the fact that inert gases are used as process gas. In principle, the melt is driven down the piece by the gas pressure. Because inert gases such as argon, nitrogen or helium are used, the cut edge does not tend to burn and is protected from oxidation. The result is a clean, oxide-free cut edge that requires no processing. Laser fusion cutting is often used to cut stainless steels.

Laser cutting, on the other hand, uses oxygen as the process gas. This leads to an exothermic reaction during cutting, and the cutting gas supports the cutting process. This allows cutting very thick materials, such as 25 mm steel. Unlike laser fusion cutting, the cut edge is dark to black due to the high thermal load. This can lead to damage in subsequent processes, such as painting or coating. However, in order to cut economically thick materials with high precision and speed, this process is a good alternative to, for example, oxy-fuel cutting.

Laser sublimation cutting refers to the cutting of materials that do not enter a molten state. This includes, for example, organic materials such as wood, veneer or fiber-reinforced plastics. These materials are not transformed into a liquid phase, but immediately into vapors. Process gas, such as air or nitrogen, has the task of conducting these vapors and burning out of the hole.

Prin cele mai importante beneficii ale taierii cu laser gasim: flexibilitatea, usurinta, rapiditatea si precizia.

In timpul procesului de debitare sau taiere cu laser, se foloseste practic o raza puternica de laser care are rolul de a taia diverse materiale precum metal, lemn, cauciuc, plastic. Aceasta tehnologie moderna a devenit o parte esentiala a procesului de productie pentru multe fabrici. Echipa Laser Processing Romania foloseste echipamente moderne de taiere laser care sa ajute la realizarea de proiecte foarte utile si benefice pentru clienti.

Serviciile noastre de debitare cu laser sunt o parte integrata a companiei noastre si sunt alese de catre multi clienti pentru ca sunt executate rapid, simplu si precis.

Cateva avantaje ale serviciilor de taiere laser sunt: – timpul de lucru foarte scurt. Acest proces este usor de realizat pentru ca este programat prin calculator si este foarte precis – fata de metodele traditionale de taiere.

Tehnologia de taiere cu laser este una foarte versatila si se poate folosi pentru orice fel de industrie – de la procese complexe pana la structuri pe o singura piesa.

Procesul de debitare laser realizat de catre echipa noastra este foarte usor de controlat, nu necesita interventie umana, doar pentru inspectare si reparatii rare.

Multe industrii de productie folosesc masini controlate numeric in ziua de azi pentru a grabi procesul de productie, aceste masini foloesc tehnologii avansate pentru a dezvolta proiecte reusite. De aceea si echipa Laser Processing utilizeaza aparatura si tehnologie de top cu scopul de a creste rapiditatea de productie.

Costurile variza de la proiect la proiect si in functie de volumul si cantitatea de material taiat.

Cand vine vremea sa analizam costurile serviciilor de debitare laser sunt putine servicii similare care pot sa ofere aceeasi precizie si acuratete de taiere. Prin taierea laser, putem sa decupam multe materiale de la metal, tabla, aluminium – la viteze rapide, cu mai putine pagube si input uman – astfel se obtin produse finale de calitate ridicata – la un cost relativ micut de productie.

Preturile pentru taierea / debitarea laser depind de mai multe elemente precum tipul de laser folosit, precizia, complexitatea de taiere.

Este adevărat că tăierea cu laser este o afacere costisitoare dacă o compari cu metodele tradiționale. Cu toate acestea, având în vedere avantajele tăierii cu laser și raportul calitate-preț, este de fapt mai rentabil decât alte metode tehnice, cum ar fi tăierea cu jet de apă.

În general, cât va costa tăierea cu laser depinde de forța de muncă implicată, timpul total și complexitățile de proiectare. Cu toate acestea, aceasta este o perspectivă foarte largă. Dacă luați în considerare factorii granulari care determină costul total de tăiere cu laser pe inch, veți găsi că următorii sunt cei mai importanți.

Puteti sa ne contactati prin email, telefon sau Whatsapp pentru mai multe detalii despre proiect.

Timpul de lucru depinde foarte mult de cantitate, volum, dificultate de munca. Contacteaza-ne pentru detalii mai multe legate de procesul de taiere cu laser.

Strada Rudeni 114, Chitila 445767-Ilfov – Bucuresti

Tarla 41, parcela 118/1

Telefon: 0217950122

info@laserprocessing.ro