Debitarea cu laser este una dintre cele mai performante metode de a tăia table de oțel, inox sau aluminiu folosită în diverse domenii industriale: construcții, auto, agro-alimentară, petrolieră, transport ș.a.

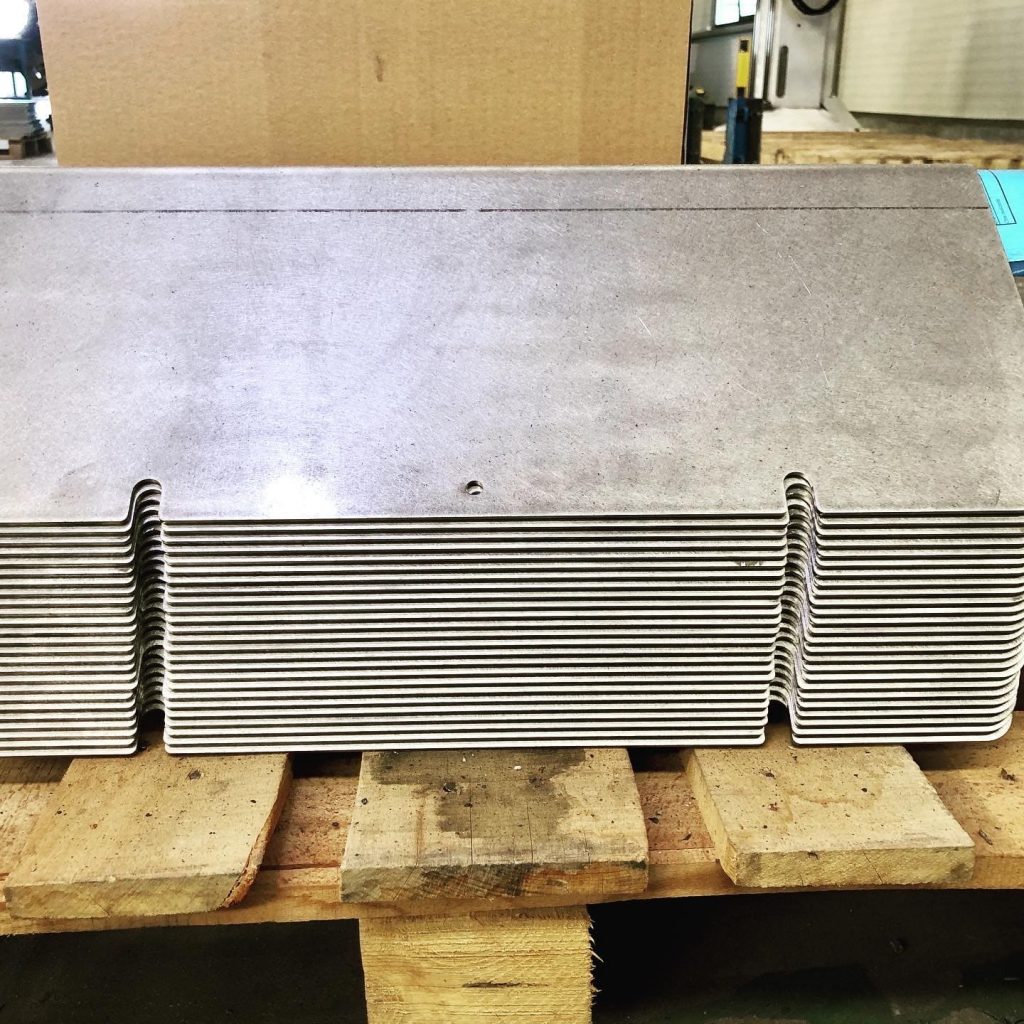

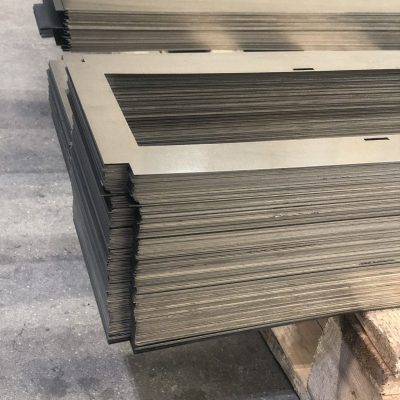

Totodată, este o tehnologie ce diminuează considerabil timpii și costurile de producție. Piesele debitate nu au bavuri sunt foarte puțin influențate termic, fiind ușor prelucrabile ulterior în cazul în care se vopsesc în câmp electrostatic sau sunt supuse tratamentelor termice și a prelucrărilor mecanice.

Avantajele certe ale tăierii cu laser metal în fața tăierii mecanice sunt reprezentate de ușurința de executare a lucrărilor dar și de precizia pe care debitarea cu laser o oferă. De asemenea, riscul de deformare de orice fel a materialului debitat cu laser este redus la minim.

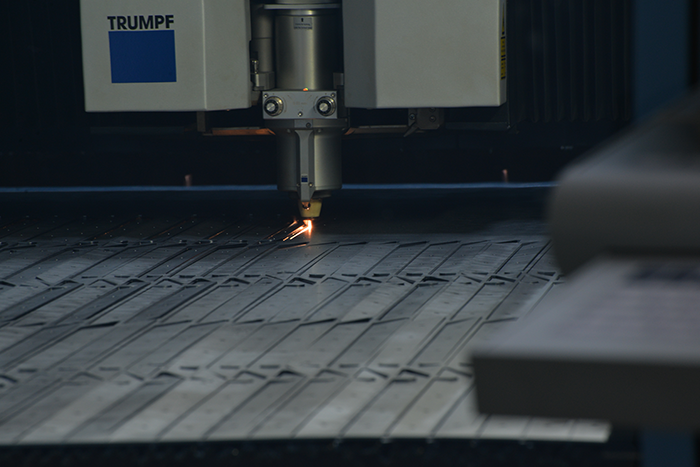

Echipa Laser Processing foloseste echipamente de taiere cu laser tabla care sunt foarte performante si precise pentru a crea piese de calitate ridicata. Procesul acesta de debitare va topi materialul in exces prin ardere sau vaporizare, dupa care un jet puternic de gaz va indeparta orice tip de rest in urma procesului de prelucrare a metalului. In final se va obtine un produs foarte bine finisat.

Serviciile noastre de debitare cu laser metal sunt executate cu utilaje moderne si performante care ne asigura garantarea succesului oricarui proiect. Astfel echipa Laser Processing este aici sa ajute orice afacere prin oferirea de servicii profesionale de taiere cu laser tabla si metal.

| Contact |

Debitarea materialelor cu ajutorul laserului este de obicei utilizată în industrie, dar în ultimii ani este folosită și în domenii tot mai diverse precum design interior, publicitate, bricolaj, arhitectură, amenajări, design de produs.

Procesul de taiere cu laserul este ideal pentru a taia otelul care are o grosime de maxim 25mm. Acest proces este unul extrem de precis si va realiza o latime a fantei care va fi foarte mica, iar in acest fel se pot taia contururi precise si chiar gauri mici cu precizie. Calitatea muchiei este foarte buna si cu rugozitate mica avand linii reziduale foarte mici.

Alt avantaj al procesului de taiere cu laser de care trebuie sa tinem cont este gradul de fiabilitate oferit. Pe langa asta, durata de viata a materialelor consumabile este foarte mare, avand un proces de automatizare foarte bun pentru ca toate operatiunile ce se efectueaza prin debitarea laser sa fie executate cu precizie maxima.

Tinand cont ca laserul nu va avea deloc contact fizic cu metalul pe care se va lucra, nu va exista nici o forma de uzura atat a echipamentului dar si a materialului – acesta din urma nu va fi deloc contaminat.Fata de mijloacele de taiere traditionale, taierea cu laser cu ajutorul masinilor moderne vor produse piese finite foarte calitative si cu margini fine.

Printre putinele metode de a reduce timpul de prelucrare si livrarea finala a materialului finit, gasim serviciile de debitare laser oferite de catre echipa Laser Processing – astfel vom reduce timpul de lucru si costurile finale fata de metodele clasice.Materialele care rezulta in urma procesului de taiere cu laser oferit de catre echipa noastra sunt foarte bine lucrate, eliminanduse riscul legat de deformarile urate sau chiar deteriorarea pieselor. Va invitam sa descoperiti si gama de servicii profesionale de prelucrari mecanice.

Cautati o firma de taiere cu laser in Romania care sa va ajute sa va duceti la bun sfarsit proiectele dumneavoastra?

Echipa Laser Processing Romania va vine acum in ajutorul dumneavoastra cu gama completa de servicii profesionale de debitare laser tabla/metal la standarde ridicate care sa va ajute sa aveti proiecte cat mai reusite si cu rezultate peste asteptari.

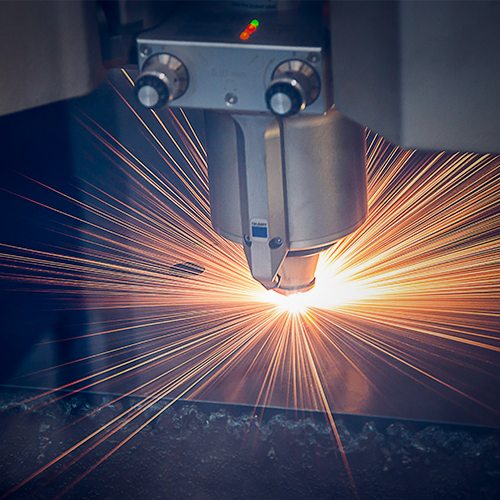

Acest proces de taiere a metalelor este foarte performant pentru ca poate sa taie diverse materiale indiferent de grosimea lor. Practic laserul este focusat intr-un punct puternic si are o precizie foarte mare, iar cand acesta va atinge piesa, se va emana o caldura mare pentru a incepe procesul de taiere.

Avand toata puterea focusata intr-un singur punct fix si cu diametru de jumatate de milimetru, se vor obtine taieturi foarte fine si precise fara zimti sau margini.

1. Se pot taia o gama variata de metale si materiale

Putem sa taiem diverse materiale necesare in prelucrarea de tip industriala de la aluminium, otel, tabla pana la elemente nemetalice precum plastic si sticla prin taierea cu laser profesional.

Astfel, acest proces de debitare tabla/metal il face foarte cautat pentru precizia lui si pentru libertatea de taiere.

2. Libertatea de miscare

Pentru ca fasciculul cu laser este concentrat intr-un singur punct la nivel local, este evident ca restul piesei va fi mai putin solicitata din punct de vedere termic. Datorita flexibilitatii ridicate, procesul de debitare tabla oferit de Laser Processing Romania este foarte des utilizat in diverse proiecte

Contact .

Dintre toate opțiunile care există în cadrul prelucrării de precizie , una dintre cele mai recente este tăierea cu laser . Pe scurt, procesul de tăiere cu laser constă în concentrarea unui fascicul de lumină pe suprafața de tăiat .

Procesul de tăiere cu laser utilizează un sistem de oglindă de precizie, o lentilă de focalizare convergentă, fasciculul laser de mare putere și sistemul CNC despre care am discutat în locul precedent . Controlează toate aspectele procesului de tăiere cu ajutorul laserelor ; de la frecvența și viteza fasciculului până la valorile capului și ale piesei, în funcție de ordinea exactă de care avem nevoie.

Unul dintre detaliile interesante despre tăierea cu laser este necesitatea utilizării unui anumit tip de material pentru evacuarea materialului tăiat . De obicei se folosește un argon sau un gaz inert sub presiune, iar aerul poate fi eficient și cu materiale nemecanice.

Acest tip de tehnică permite o creștere a productivității , cu marginile tăiate curate , se previne supraîncălzirea , rezistența la coroziune , decolorarea este redusă, nu se formează rugină și suprafețele sunt lipsite de zgură.

Nu generează la fel de mult așchie ca procesul de tăiere convențional.

Este perfect pentru tăierea preliminară și finală .

Poate fi folosit pentru a crea contururi de suprafață, ajustări ale siluetei sau piese care trebuie manipulate .

Dacă debitarea este corectă , nu există creste .

Tăierea cu laser a metalelor poate fi aplicat la orice material , fie moale sau tare sunt utilizate. Este utilizat în mod obișnuit în toate tipurile de aliaje rezistente la căldură , cum ar fi ceramica, materialele compozite , pielea , țesăturile , siciliul , plasticul etc. În funcție de material , radiația este diferită.

Dacă sunteți interesat de lucrări de prelucrare de precizie, cum ar fi tăierea cu laser , prelucrarea sincronizată este soluția dvs. Suntem alături de dvs. cu sfaturi și acțiuni pentru fiecare proces pe care doriți să-l mecanizați

Tăierea cu laser este un proces de fabricație fără tăiere pentru separarea materialelor de orice fel. Prin utilizarea radiației laser, materialul este practic topit și vaporizat folosind diverse tehnologii, astfel încât se creează un spațiu de tăiere și materialul este separat în mod specific. Decupare cu laser este realizată cu toate lungimile de undă laser care sunt disponibile, dar mai ales cu CO 2 lasere și lasere cu fibre.

Astăzi, tăierea cu laser a metalelor are o gamă largă de aplicații și este greu de imaginat producția industrială fără ea. Metalele, materialele plastice sau materialele organice pot fi tăiate precis și economic cu ajutorul instrumentului laser. Există, de asemenea, multe aplicații în care nu există aproape nicio alternativă la tăierea cu laser, cum ar fi tăierea tablelor foarte subțiri <0,05 mm. Tăierea cu laser este utilizată în toate industriile, de la industria auto, tehnologia medicală, ingineria mecanică la industria ambalajelor.

Tăierea cu laser este fără contact și are scoruri cu timpi de proces scurți și precizie ridicată.

În afară de gazele de proces, nu sunt necesare auxiliare precum lubrifiantul de răcire etc.

Aproape toate materialele pot fi tăiate cu alegerea corectă a laserului.

Deoarece nu se utilizează instrumente, tehnologia sistemului nu este supusă uzurii și, prin urmare, este ieftină.

Reelaborarea componentelor tăiate nu este de obicei necesară, cu parametrii de proces corecți este posibilă tăierea aproape fără bavuri, ceea ce este adesea un dezavantaj major la perforarea tablelor de metal, de exemplu.

Tăierea cu laser este extrem de flexibilă, ceea ce înseamnă că producția dintr-o singură parte a contururilor de tăiere complexe poate fi, de asemenea, implementată economic.

Debitarea cu laser cu duză

Tăierea cu laser în combinație cu o duză de tăiere este cea mai comună variantă a procesului.Cu acest tip de tăiere, fasciculul laser este ghidat printr-o duză de tăiere și focalizat. În funcție de procesul de tăiere, se utilizează diverse gaze de proces, care sunt suflate coaxial prin duză în gaură la presiune ridicată.

Tăierea prin fuziune cu laser este utilizată pe metale și se caracterizează prin faptul că gazele inerte sunt utilizate ca gaz de proces. În principiu, topitura este condusă în jos afară din bucată de presiunea gazului. Deoarece se folosesc gaze inerte, cum ar fi argonul, azotul sau heliul, marginea tăiată nu tinde să ardă și este protejată de oxidare. Rezultatul este o margine tăiată curată, fără oxid, care nu necesită prelucrare. Tăierea prin fuziune cu laser este adesea utilizată pentru tăierea oțelurilor inoxidabile.

Tăierea cu laser, pe de altă parte, folosește oxigenul ca gaz de proces. Acest lucru duce la o reacție exotermă în timpul tăierii, iar gazul de tăiere susține procesul de tăiere. Acest lucru permite tăierea materialelor foarte groase, cum ar fi oțelul de 25 mm. Spre deosebire de tăierea prin fuziune cu laser, marginea tăiată este întunecată până la neagră datorită sarcinii termice ridicate. Acest lucru poate duce la afectări în procesele ulterioare, cum ar fi vopsirea sau acoperirea. Cu toate acestea, pentru a tăia materialele groase din punct de vedere economic cu o precizie și viteză ridicate, acest proces este o alternativă bună la, de exemplu, tăierea cu oxi-combustibil.

Tăierea prin sublimare cu laser se referă la tăierea materialelor care nu intră într-o stare topită. Aceasta include, de exemplu, materiale organice precum lemnul, furnirul sau materialele plastice armate cu fibre. Aceste materiale nu sunt transformate într-o fază lichidă, ci imediat în vapori. Gazul de proces, cum ar fi aerul sau azotul, are sarcina de a conduce acești vapori și de a arde din gaură.

Prin cele mai importante beneficii ale taierii cu laser gasim: flexibilitatea, usurinta, rapiditatea si precizia.

In timpul procesului de debitare sau taiere cu laser, se foloseste practic o raza puternica de laser care are rolul de a taia diverse materiale precum metal, lemn, cauciuc, plastic. Aceasta tehnologie moderna a devenit o parte esentiala a procesului de productie pentru multe fabrici. Echipa Laser Processing Romania foloseste echipamente moderne de taiere laser care sa ajute la realizarea de proiecte foarte utile si benefice pentru clienti.

Serviciile noastre de debitare cu laser sunt o parte integrata a companiei noastre si sunt alese de catre multi clienti pentru ca sunt executate rapid, simplu si precis.

Cateva avantaje ale serviciilor de taiere laser sunt: – timpul de lucru foarte scurt. Acest proces este usor de realizat pentru ca este programat prin calculator si este foarte precis – fata de metodele traditionale de taiere.

Tehnologia de taiere cu laser este una foarte versatila si se poate folosi pentru orice fel de industrie – de la procese complexe pana la structuri pe o singura piesa.

Procesul de debitare laser realizat de catre echipa noastra este foarte usor de controlat, nu necesita interventie umana, doar pentru inspectare si reparatii rare.

Multe industrii de productie folosesc masini controlate numeric in ziua de azi pentru a grabi procesul de productie, aceste masini foloesc tehnologii avansate pentru a dezvolta proiecte reusite. De aceea si echipa Laser Processing utilizeaza aparatura si tehnologie de top cu scopul de a creste rapiditatea de productie.

Costurile variza de la proiect la proiect si in functie de volumul si cantitatea de material taiat.

Cand vine vremea sa analizam costurile serviciilor de debitare laser sunt putine servicii similare care pot sa ofere aceeasi precizie si acuratete de taiere. Prin taierea laser, putem sa decupam multe materiale de la metal, tabla, aluminium – la viteze rapide, cu mai putine pagube si input uman – astfel se obtin produse finale de calitate ridicata – la un cost relativ micut de productie.

Preturile pentru taierea / debitarea laser depind de mai multe elemente precum tipul de laser folosit, precizia, complexitatea de taiere.

Este adevărat că tăierea cu laser este o afacere costisitoare dacă o compari cu metodele tradiționale. Cu toate acestea, având în vedere avantajele tăierii cu laser și raportul calitate-preț, este de fapt mai rentabil decât alte metode tehnice, cum ar fi tăierea cu jet de apă.

În general, cât va costa tăierea cu laser depinde de forța de muncă implicată, timpul total și complexitățile de proiectare. Cu toate acestea, aceasta este o perspectivă foarte largă. Dacă luați în considerare factorii granulari care determină costul total de tăiere cu laser pe inch, veți găsi că următorii sunt cei mai importanți.

Puteti sa ne contactati prin email, telefon sau Whatsapp pentru mai multe detalii despre proiect.

Timpul de lucru depinde foarte mult de cantitate, volum, dificultate de munca. Contacteaza-ne pentru detalii mai multe legate de procesul de taiere cu laser.

Strada Rudeni 114, Chitila 445767-Ilfov – Bucuresti

Tarla 41, parcela 118/1

Telefon: 0217950122

info@laserprocessing.ro